If we don’t have it in stock, we’ll custom-make it and will meet your timeline.

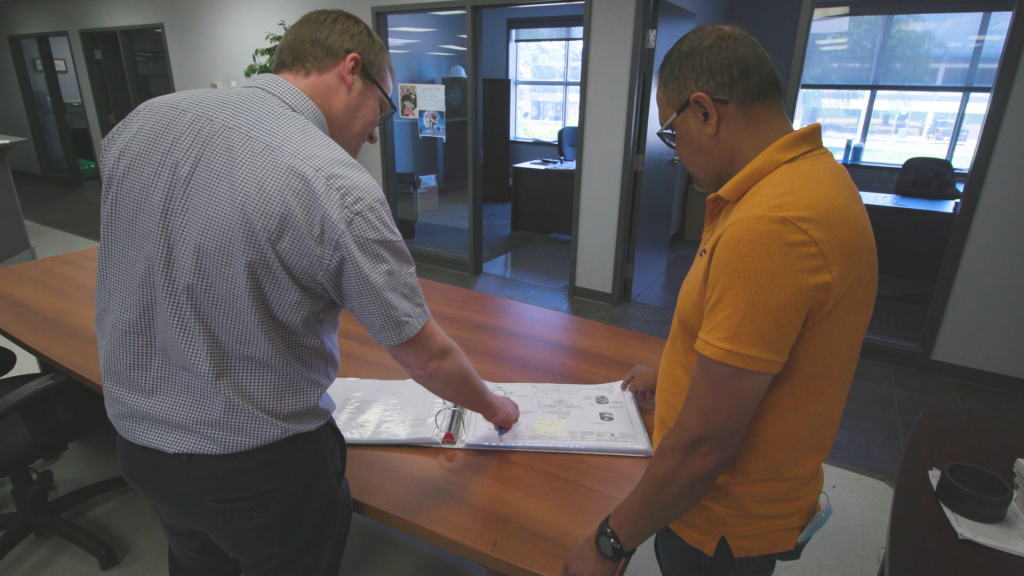

The hub of our company is our 80,000 square foot manufacturing facility in Edmonton, Alberta. It’s here that our team of engineers and product designers work with our clients to deliver custom machine shop and engineering solutions.

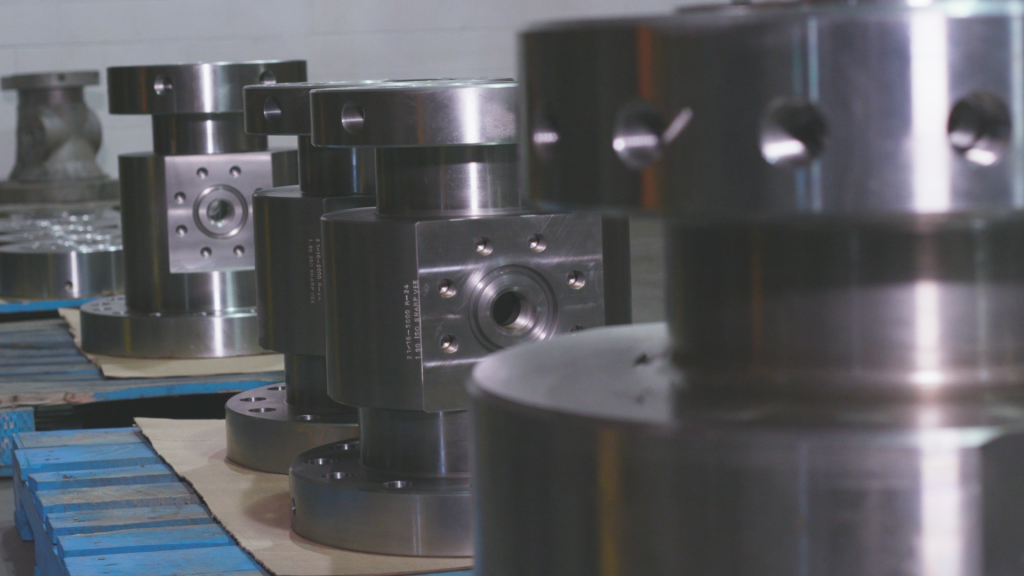

Our API 6A Licensed Facility is supported by 21 state-of-the-art machines capable of producing stock from ¼” to 50” diameter with all product manufactured and qualified as per API standards.

Redco is the primary manufacturing and supply arm of Great North. They maintain world class manufacturing capabilities by managing full-service in-house machine shop and engineering and strong national and international procurement processes. Redco is an industry leader in manufacturing, repair, re-manufacture and custom-built wellhead and valve products for 20 years.

Since incorporating in 2003, Great North has been the fastest growing wellhead and frac company in western Canada. Our 80,000 square foot manufacturing, repair, and re-manufacturing facility supports all of our branches across western Canada and is committed to meeting all of our customer requirements. The facility is certified to ISO 9001 and API 6A (21st edition) and re-manufactures wellhead equipment in accordance with ISO 10423 and is COR certified.

Great North | Copyright© 2022