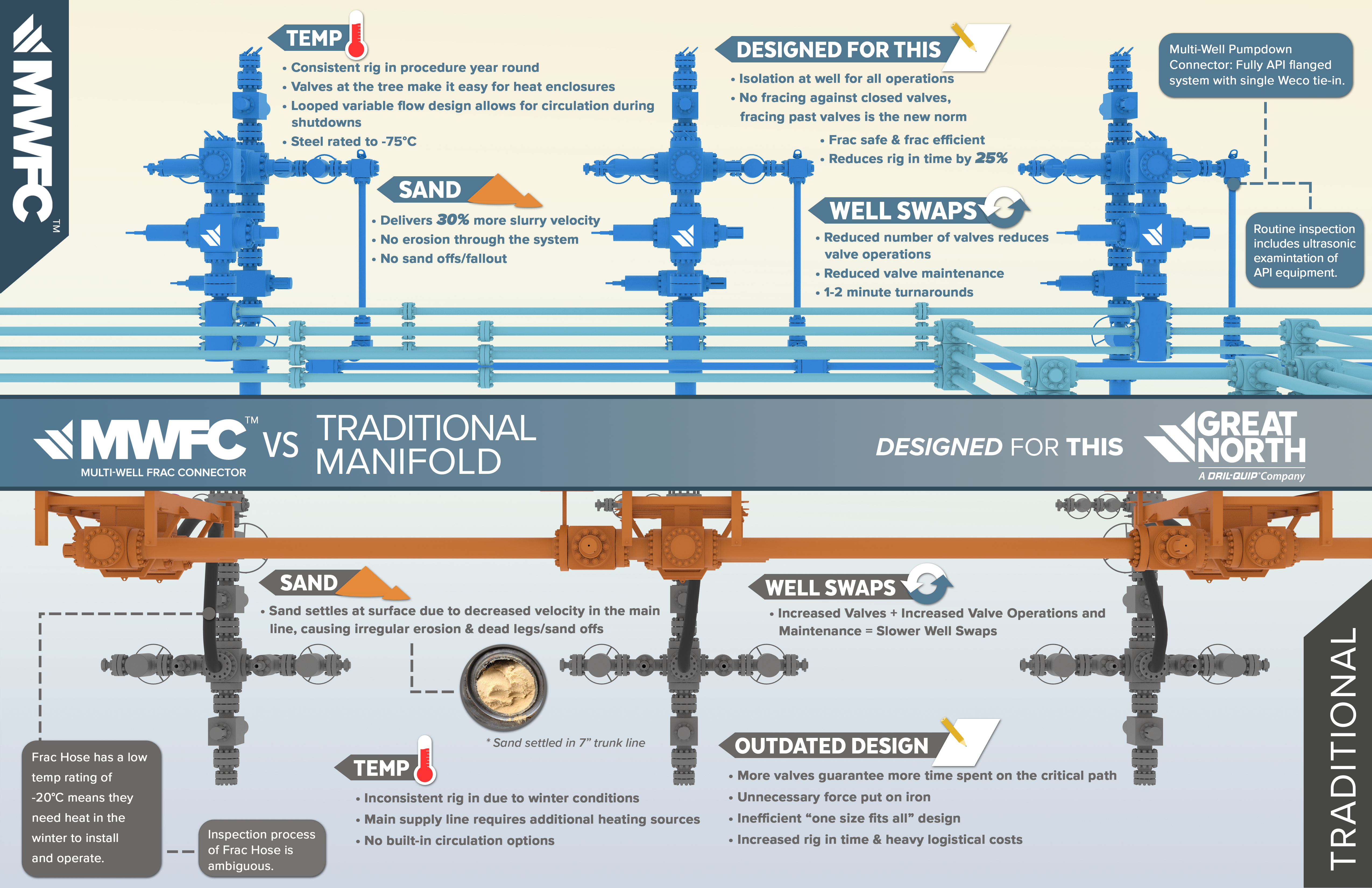

About the Multi-Well Frac Connector

The Multi-Well Frac Connector (MWFC) is efficient and flexible. It reduces the total number of valves required and delivers quicker times between fracs. It is also sized for any range of pump rate and is adaptable to any well spacing or completions program.